When it comes to manufacturing plastic parts, selecting the right process is crucial to ensure quality, cost-effectiveness, and efficiency. Two popular methods for producing plastic parts are urethane casting and injection molding. Both have their unique advantages and applications, but choosing the best one for your project depends on various factors. In this blog, we’ll explore the differences, benefits, and ideal use cases for urethane casting and injection molding to help you make an informed decision.

Understanding Urethane Casting

Urethane casting is a manufacturing process where liquid polyurethane is poured into a silicone mold to create parts. This method is ideal for producing small quantities of parts and prototypes with high fidelity and intricate details.

Advantages of Urethane Casting:

Cost-Effective for Low Volumes: Urethane casting is economical for producing small batches, making it an excellent choice for prototypes and short production runs.

Quick Turnaround Time: With urethane casting, the mold preparation and production process are relatively quick, allowing for fast prototyping and iteration.

High Detail and Finish Quality: Urethane casting can produce parts with intricate details and smooth surface finishes, closely mimicking the final production parts.

Material Versatility: A wide range of urethane materials is available, offering different properties such as flexibility, hardness, and durability.

Lower Tooling Costs: The silicone molds used in urethane casting are less expensive to produce compared to the steel molds required for injection molding.

Ideal Applications for Urethane Casting:

•Prototyping and concept models

•Custom parts for low-volume production

•Pre-production testing

•Functional testing of parts with complex geometries

Understanding Injection Molding

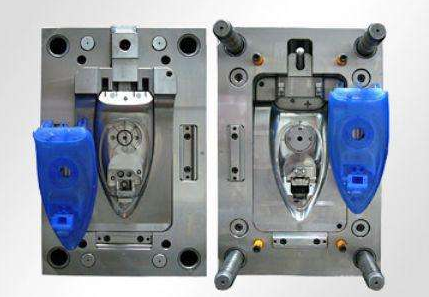

Injection molding is a manufacturing process where molten plastic is injected into a metal mold under high pressure to produce parts. This method is highly efficient for mass production and can produce parts with consistent quality and high precision.

Advantages of Injection Molding:

Cost-Effective for High Volumes: While the initial tooling costs are high, injection molding becomes more economical for large production runs due to lower per-part costs.

High Precision and Consistency: Injection molding offers excellent repeatability, ensuring that each part produced is identical and meets stringent quality standards.

Wide Range of Materials: A vast array of thermoplastics can be used in injection molding, providing options for parts requiring specific mechanical properties and performance.

Efficient Production: Injection molding can produce thousands of parts in a short time, making it ideal for high-volume manufacturing.

Durability and Longevity: The steel molds used in injection molding are durable and can produce a high number of parts before requiring maintenance or replacement.

Ideal Applications for Injection Molding:

•High-volume production of plastic parts

•Consumer products and electronics

•Automotive components

•Medical devices and packaging

•Industrial and commercial parts

Comparing Urethane Casting and Injection Molding

Cost:

•Urethane Casting: Lower initial costs and tooling expenses; cost-effective for low-volume production.

•Injection Molding: Higher initial tooling costs but lower per-part costs for large production runs.

Production Volume:

•Urethane Casting: Best suited for low to medium volumes (1-1000 parts).

•Injection Molding: Ideal for high-volume production (1000+ parts).

Lead Time:

•Urethane Casting: Faster lead time for small batches and prototypes.

•Injection Molding: Longer lead time due to mold fabrication but faster production for high volumes.

Part Complexity and Detail:

•Urethane Casting: Excellent for complex geometries and fine details.

•Injection Molding: Capable of high precision but may require complex and costly mold designs for intricate parts.

Choosing the Right Process for Your Project

The decision between urethane casting and injection molding depends on several factors:

•Production Volume: For low to medium volumes, urethane casting is more cost-effective. For high-volume production, injection molding is the better choice.

•Budget: Consider the initial tooling costs and per-part costs. Urethane casting requires a lower upfront investment.

•Lead Time: If you need a fast turnaround for prototypes or short runs, urethane casting offers quicker lead times.

•Part Complexity: Urethane casting excels at producing parts with intricate details, while injection molding provides high precision for large quantities.

•Material Properties: Evaluate the specific material requirements for your parts and choose the process that offers the best material options.

Conclusion

Both urethane casting and injection molding have their distinct advantages and are suited for different project needs. By understanding the strengths and limitations of each process, you can make an informed decision that aligns with your project’s requirements, budget, and timeline. Whether you need high-detail prototypes or large-scale production, selecting the right manufacturing method will ensure the success of your project.

Post time: Jun-14-2024