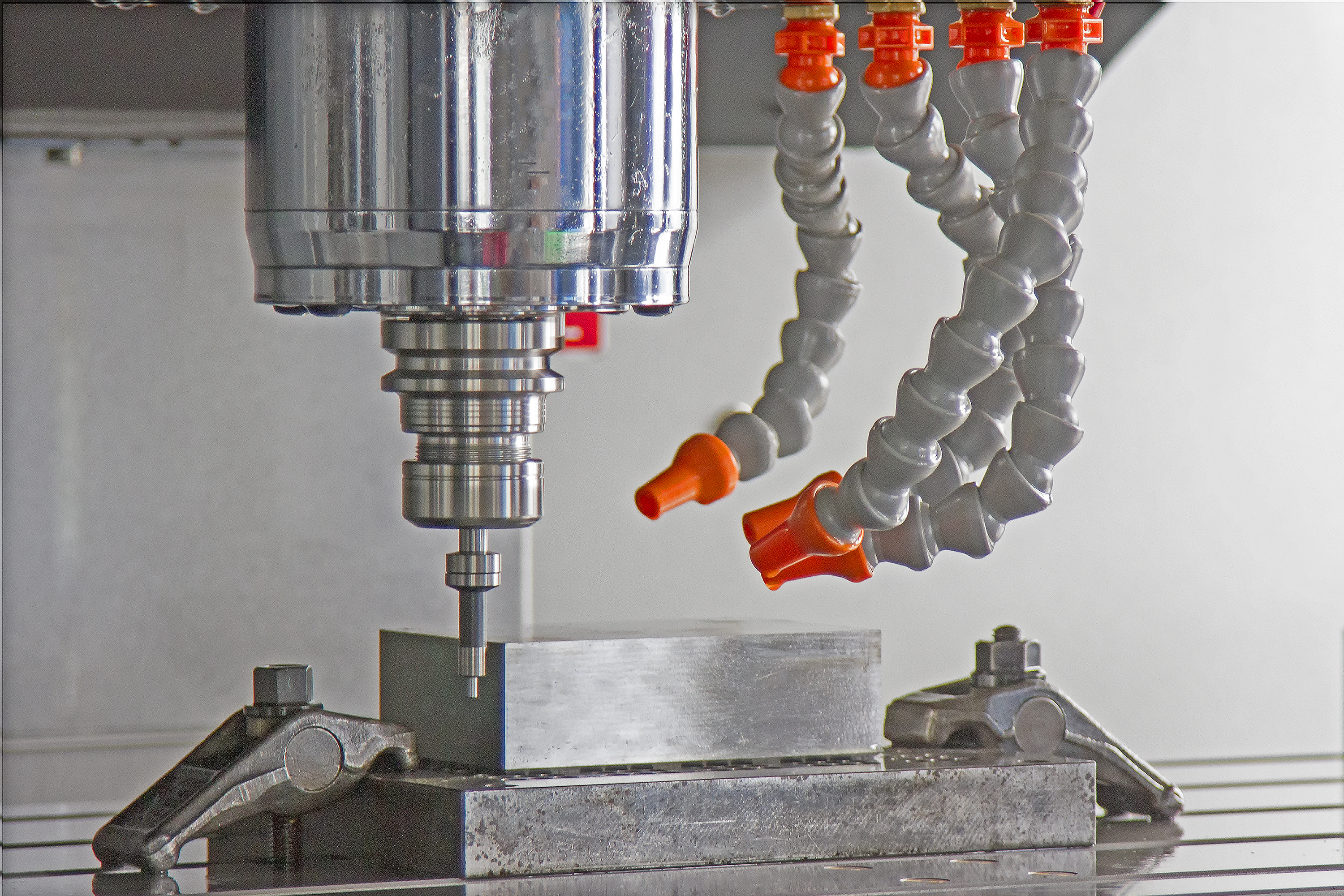

In the realm of manufacturing and engineering, Computer Numerical Control (CNC) machining has revolutionized the way components and products are created. This sophisticated technology enables precise and efficient machining of various materials, catering to a wide array of industries ranging from automotive to aerospace, from electronics to medical devices. However, with the multitude of materials available, choosing the right one for your CNC project can be a daunting task. Fear not, for this guide will walk you through the factors to consider when selecting the perfect CNC material for your specific requirements.

1. Understand Your Project Requirements

Before diving into the world of materials, it's essential to have a clear understanding of your project's specifications. Consider factors such as:

Functional requirements: What will the final product be used for? Is it a structural component, a decorative piece, or a part subjected to high temperatures or corrosive environments?

Design intricacies: Does your design feature intricate details or complex geometries that require specific material properties?

Quantity and budget: How many parts do you need, and what is your budget for material procurement?

By defining these parameters, you can narrow down the material options that best suit your project.

2. Material Properties

Different materials offer distinct properties that can significantly impact the performance and characteristics of your final product. Some key properties to consider include:

Strength and durability: Depending on the application, you may require materials with high tensile strength, impact resistance, or wear resistance.

Machinability: Consider the ease with which the material can be machined using CNC techniques. Some materials may require specialized tooling or expertise.

Thermal and electrical conductivity: For applications involving heat dissipation or electrical conductivity, choose materials with suitable thermal and electrical properties.

Corrosion resistance: If your project will be exposed to harsh environments or chemicals, opt for materials with corrosion-resistant properties.

3. Material Options

Once you've identified your project requirements and desired material properties, explore the various material options available for CNC machining. Some common materials include:

Metals: Aluminum, stainless steel, brass, titanium, and copper are popular choices for their excellent strength-to-weight ratio, machinability, and versatility.

Plastics: ABS, acrylic, nylon, and polycarbonate offer lightweight, cost-effective solutions with good chemical resistance and design flexibility.

Composites: Carbon fiber, fiberglass, and laminates combine high strength with lightweight properties, making them ideal for aerospace and automotive applications.

4. Consider Machining Constraints

While CNC machining offers remarkable precision and flexibility, certain materials may pose challenges during the machining process. Factors such as tool wear, chip formation, and surface finish can influence the choice of material. It's essential to consult with experienced CNC machinists who can provide insights into the feasibility and optimization of machining specific materials.

5. Prototype and Test

Before committing to large-scale production, it's advisable to create prototypes using different materials to evaluate their performance against your project requirements. Conduct thorough testing and analysis to assess factors such as mechanical strength, dimensional accuracy, and surface finish. This iterative process allows you to fine-tune your material selection and optimize your final design.

Conclusion

Selecting the right material for your CNC project is a critical decision that can impact the quality, performance, and cost-effectiveness of your final product. By understanding your project requirements, considering material properties, exploring diverse material options, and collaborating with experienced CNC machinists, you can confidently choose the perfect material that aligns with your vision and objectives. With careful consideration and informed decision-making, you'll embark on a journey towards CNC machining success, unlocking endless possibilities for innovation and excellence.

Post time: Mar-26-2024