In CNC machining Process , Plastic materials play a crucial role in fabricating precise components for a myriad of applications. From prototypes to end-use parts, selecting the appropriate plastic material is paramount for achieving desired functionality, durability, and cost-effectiveness. In this guide, we'll explore five commonly used CNC plastic materials – ABS, PC, Nylon, PMMA, and UHMW-PE – and provide insights into how to choose the perfect material for your project.

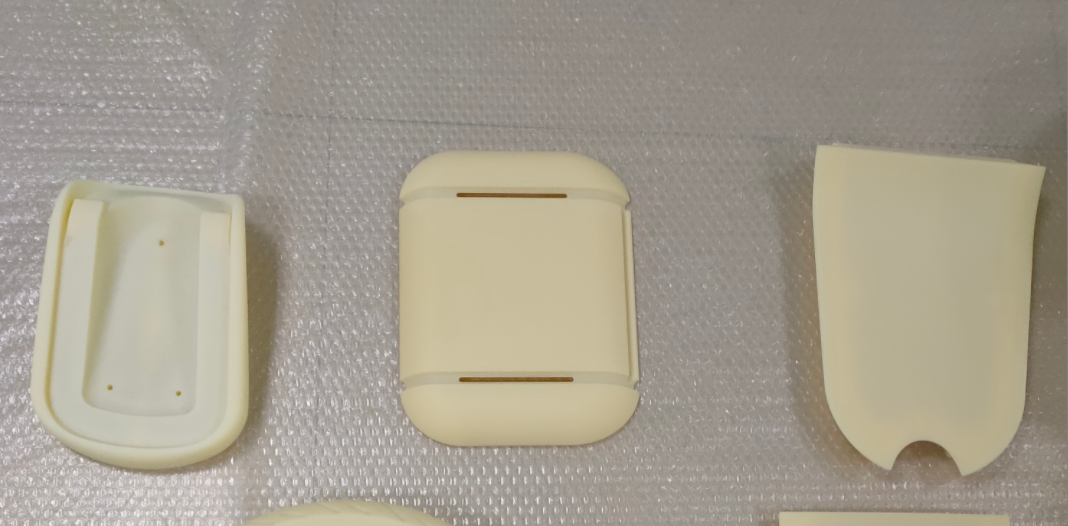

1. ABS (Acrylonitrile Butadiene Styrene)

ABS is a versatile thermoplastic known for its excellent impact resistance, durability, and machinability. Here's what to consider when choosing ABS for your CNC project:

Application: ABS is suitable for a wide range of applications, including automotive parts, consumer goods, and prototyping.

Properties: It offers good mechanical strength, high impact resistance, and can be easily machined to precise tolerances.

Considerations: While ABS provides good overall performance, it may not be the best choice for applications requiring high heat resistance or chemical resistance.

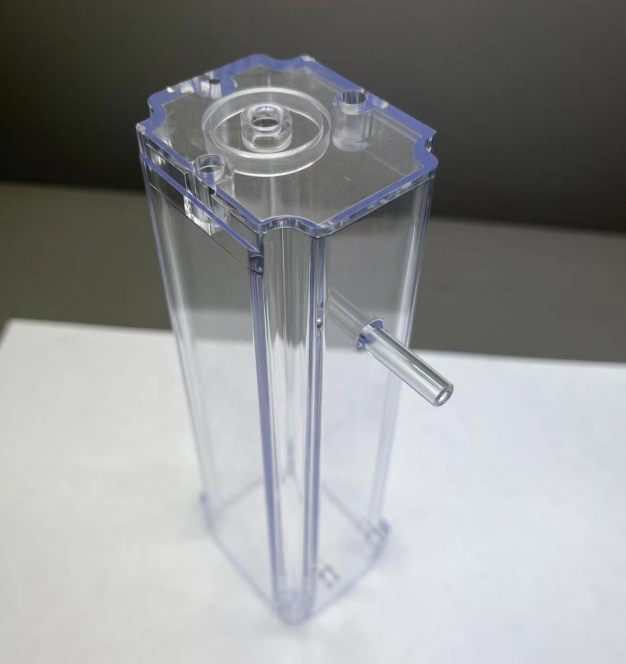

2.PC (Polycarbonate)

Polycarbonate is a transparent thermoplastic prized for its exceptional impact resistance and optical clarity. Here are key considerations for selecting PC:

Application: PC is commonly used in applications such as safety equipment, electrical enclosures, and automotive components.

Properties: It boasts high impact strength, excellent transparency, and good heat resistance.

Considerations: PC can be more challenging to machine compared to other plastics due to its toughness and tendency to produce chips during machining.

3.Nylon (Polyamide)

Nylon is a versatile engineering thermoplastic renowned for its high strength, toughness, and chemical resistance. Here's what to keep in mind when choosing Nylon for CNC machining:

Application: Nylon is ideal for applications requiring high strength, such as gears, bearings, and structural components.

Properties: It offers excellent abrasion resistance, low friction coefficient, and good chemical resistance.

Considerations: Nylon absorbs moisture, which can affect dimensional stability and machining accuracy if not properly accounted for during CNC machining.

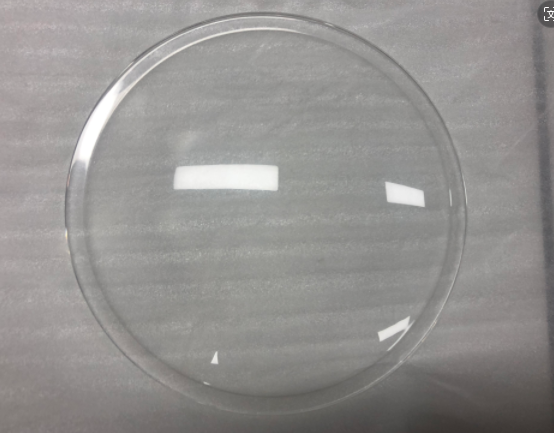

4. PMMA (Polymethyl Methacrylate)

PMMA, commonly known as acrylic, is a transparent thermoplastic valued for its optical clarity and ease of machining. Consider the following when selecting PMMA for your CNC project:

Application: PMMA is often used in signage, display cases, optical components, and lighting fixtures.

Properties: It offers excellent optical clarity, good impact resistance, and can be easily machined to intricate shapes.

Considerations: PMMA is prone to scratching and may exhibit poor chemical resistance to certain solvents and cleaners.

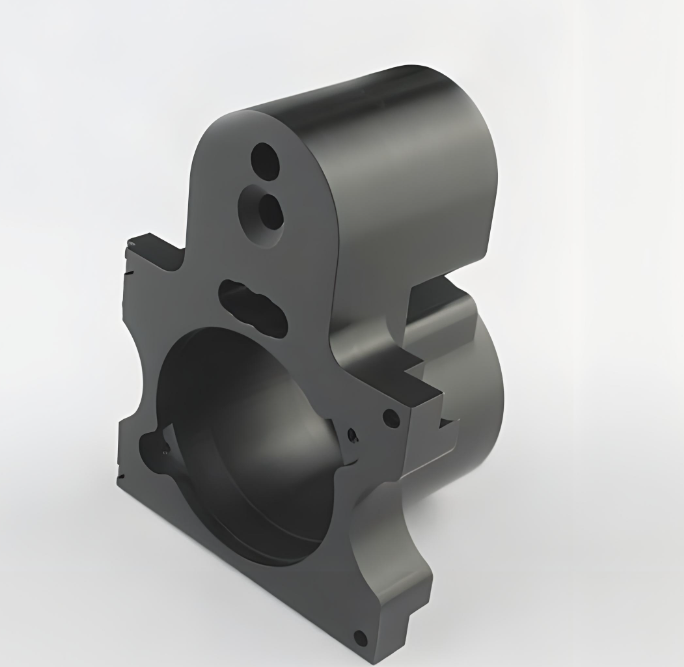

5. UHMW-PE (Ultra-High Molecular Weight Polyethylene)

UHMW-PE is a high-performance thermoplastic known for its exceptional wear resistance, low friction coefficient, and self-lubricating properties. Here's what to consider when choosing UHMW-PE:

Application: UHMW-PE is commonly used in applications requiring low friction, such as conveyor components, bearings, and wear strips.

Properties: It offers outstanding wear resistance, high impact strength, and excellent chemical resistance.

Considerations: UHMW-PE can be more challenging to machine due to its high molecular weight and tendency to produce stringy chips during machining.

When choosing the right CNC plastic material for your project, it's essential to carefully consider factors such as application requirements, material properties, and machining considerations. By understanding the unique characteristics of ABS, PC, Nylon, PMMA, and UHMW-PE, you can make informed decisions that optimize performance, durability, and cost-effectiveness for your CNC machining endeavors. Whether you're fabricating prototypes, custom parts, or end-use products, selecting the perfect plastic material sets the foundation for success in your manufacturing journey.

Post time: Mar-26-2024