Plastic Injection Molding Service For You

Injection molding is cost-effective way to produce plastic parts in small and large batches. It is a repeatable process that enable us to delivery several components with consistent quality. Foxstar is an experienced tooling manufactures offering the best solution for your projects. Our custom plastic injection molding service including on-demand prototype and mass production.

Injection Molding from Prototype to Production

Rapid Tooling (Soft Tooling )

It is a type of injection mold tooling, testing and validating of the parts in product development process, Rapid tooling process allows you to get design feedback, functional test and validation of market interest in short time.

Production Tooling

We make high-quality production molds for high quantities plastic parts production. With high-strength, durable steel material, our production tooling is suitable for producing large volume of plastic parts. We can provide different materials and production methods based on your requirements.

Our Injection Molding Process

Request Instant Quote

When gathering all the information for quote, our engineer will delivery the quote within 24 hours.

DFM Report

Our design for manufacturing review enables us to find any defects or concerns beforehand and provide suggestions for a more workable design.

Mold Flow Analysis

With predictive modeling software allows us to understand how the molten material will behave when it enters the mold, allowing for further improvements to the design.

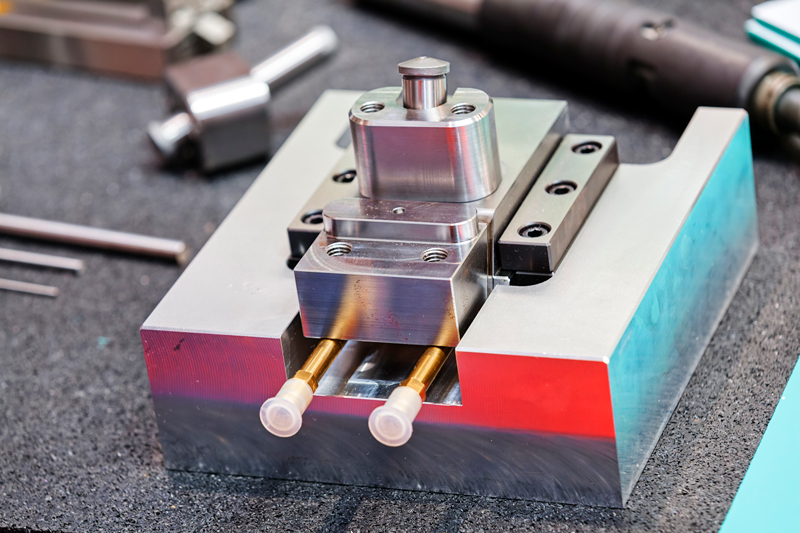

Mold Tooling Manufacture

We apply high-quality CNC machining to make the injection mold, ensure the mold is ready to be used.

T1 Sample Inspection

T1 samples will be sent to you for inspection prior to making plastics part to guarantee quality and precision.

Low Volume Production

After T1 sample is approved, we start batch production.

Strict Inspection

We follow ISO 2768 to ensure tolerance requirement.

Delivery

We work with Our logistic partner to schedule a timely delivery to your region.

Why Choose US For Plastic Injection Molding Service

Foxstar is committed to provide advanced injection molding service, with solution of tooling design, material selection and surface finish, prototype and production and quality assurance. Our team provide professional technique supports, delivery precise parts, Foxstar is looking forward to meeting your manufactures demands.

NO MOQ

No minimum order requirement to reduce injection mold cost and cut the time from design to production.

High efficiency

With a strong domestic supplied chain and certified factories, we aim to accelerating the product development cycle and bridge the production of your injection molded parts as fast as possible.

Tight Tolerance and High Quality

By ISO 2768 Standards, helping us to meet tight tolerance requirement, Foxstar delivery various size and complex design plastic injection molded parts.

Injection Molding Specialists

With 11 years of experience in the injection molding industry, efficiently complete a turnaround from prototyping to production.

Plastic Injection Molding Material

We have side range of material selection of more than 50 thermoplastic materials, check out some of plastic material that you could use on your parts.

| Material | Description | Common Application |

| ABS | High Stability, easy to process | Automotive, housing, toys etc |

| POM (Delrin) | Low Friction, High Stiffness | Rollers, geats, handles etc |

| PC(Polycarbonate) | High temperature resistance dimensional stability | Automotive, lighting, housing, etc |

| PA (Nylon) | High chemical heat resistance, High abrasion and wear resistance | Gears and sliders, large parts, general-purpose, wear & heat-resistance applications etc |

| PMMA (Acrylic) | good tensile, scratch resistant | Lighting housing ,signs etc |

| PEEK | high temperature, chemical, and radiation resistance with low moisture absorption. | Metal-alternative for high-stress applications |

| PP((Polypropylene)) | Good resistance. Food-safe grades available | Containers, laboratory equipment etc |

| PE (Polyethylene) | low melting point, high ductility, high impact strength, and low friction. | Toys, Packaging etc |

Additives and Fibers

Standard plastic materials may not meet custom injection molding parts requirements. Additives and fibers can be added to improve aesthetic and functional properties, providing additional features for injection molded parts.

Material: PC+ Glass-Filled, PP+ Glass-Filled, Nylon - Glass Filled & 6/6, PBT+Glass Filled etc.

Surface Finishes for Plastic Injection Molding

Improve surface quality of plastic injection molded parts with excellent surface finishing options. Foxstar offers extensive options of surface treatments to improve appearance of injection parts. These efficient secondary operations also improve the mechanical qualities of prototypes and production parts. Please Check our below for Surface Finishes for Plastic Injection Molding.

| Glossy | Semi-Glossy | Matte | Texture |

| SPI-A2 | SPI-B1 | SPI-C1 | MT(Mold-Tech) |

| SPI-A3 | SPI-B2 | SPI-C2 | VDI (Verein Deutscher Ingenieure) |

| SPI-B3 | SPI-C3 |

Plastic Injection Molded Parts Gallery

Foxstar is specialized in custom plastic injection mold and injection plastic parts for robotic, lighting, automotive, electronics, as well as general industrial OEM applications.