What’s Extrusion

Extrusion is a versatile and efficient manufacturing process that has revolutionized the way industries produce a wide range of products. At Foxstar, we are experts in leveraging the power of extrusion to meet your unique manufacturing needs. With over 12 years of experience in the field, we have honed our expertise in this cutting-edge technology to provide innovative solutions for various industries.

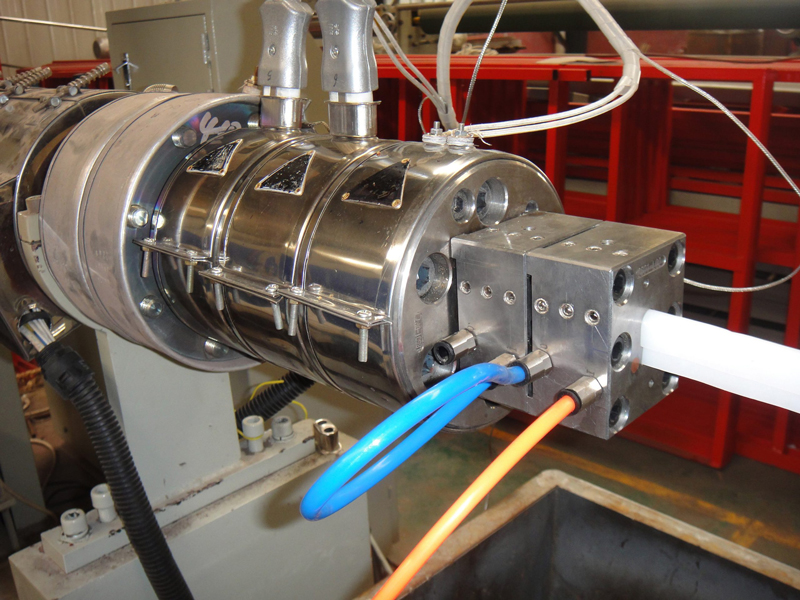

How Does It Work?

The extrusion process begins with carefully selected raw materials, which are heated to a specific temperature. Once the material reaches its ideal state, it is forced through a die with the desired shape. As the material passes through the die, it takes on the profile of the die's opening. This results in a continuous length of the formed product, which can be cut to the desired length.

Extrusion Material

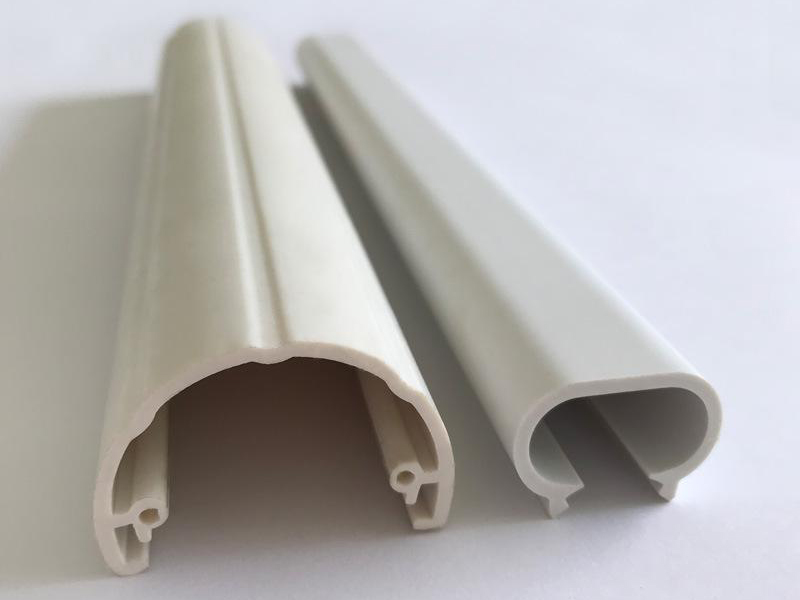

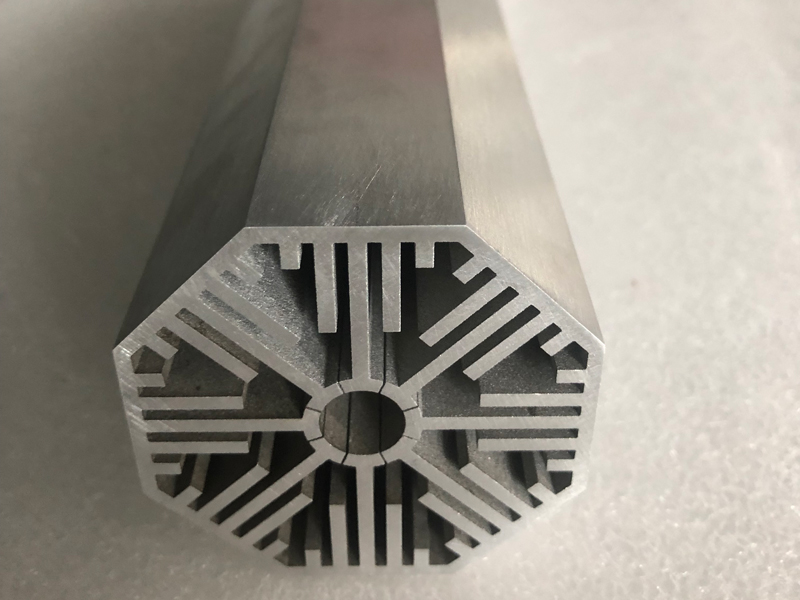

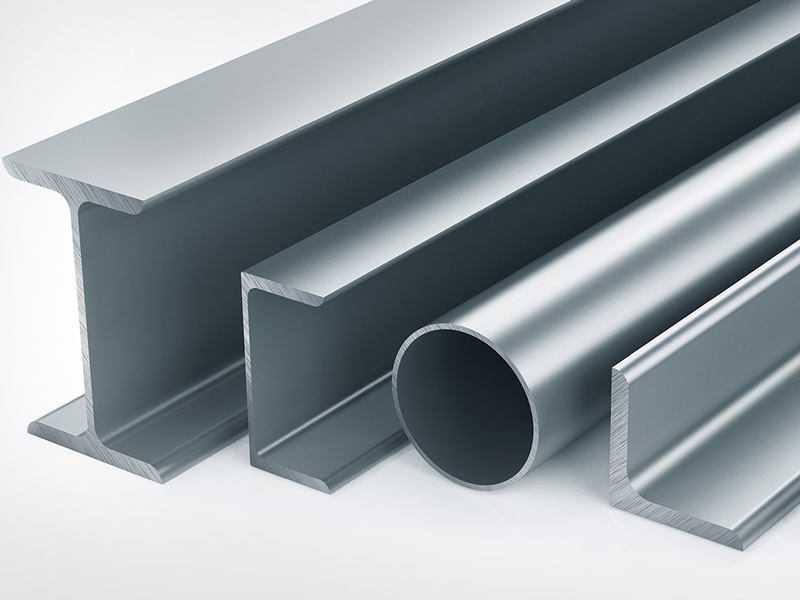

At Foxstar0, we provide metal extrusion and Plastic extrusion and different surface finish.

| Metal Extrusion | Plastic Extrusion | |

| Material | Aluminum, steel, stainless steel, brass, etc. | PC, ABS, PVC, PP, PE etc. |

| Application | window frames, doorframes, motor housings, household appliances, automotive chassis, heat sinks etc | Pipes, weather strips, windshield wipers, door seal etc |

| Surface Finish | Powder coating, Wet painting, plating, brush, etc. | Painting, plating, brush, texture, smooth etc. |

| Lead Time | 15-20days | 15-20days |

Gallery of Extrusion

Advantages of Extrusion at Foxstar

No MOQ, we can make prototype, low-volume production or high qty production.

We can customize part according to your demands and keep the mold at Foxstar for future orders.

other supporting services are available at Foxstar, such as CNC post-processing, bending, surface finish etc.

We provide one-stop service for your project to guarantee lead time and quality.