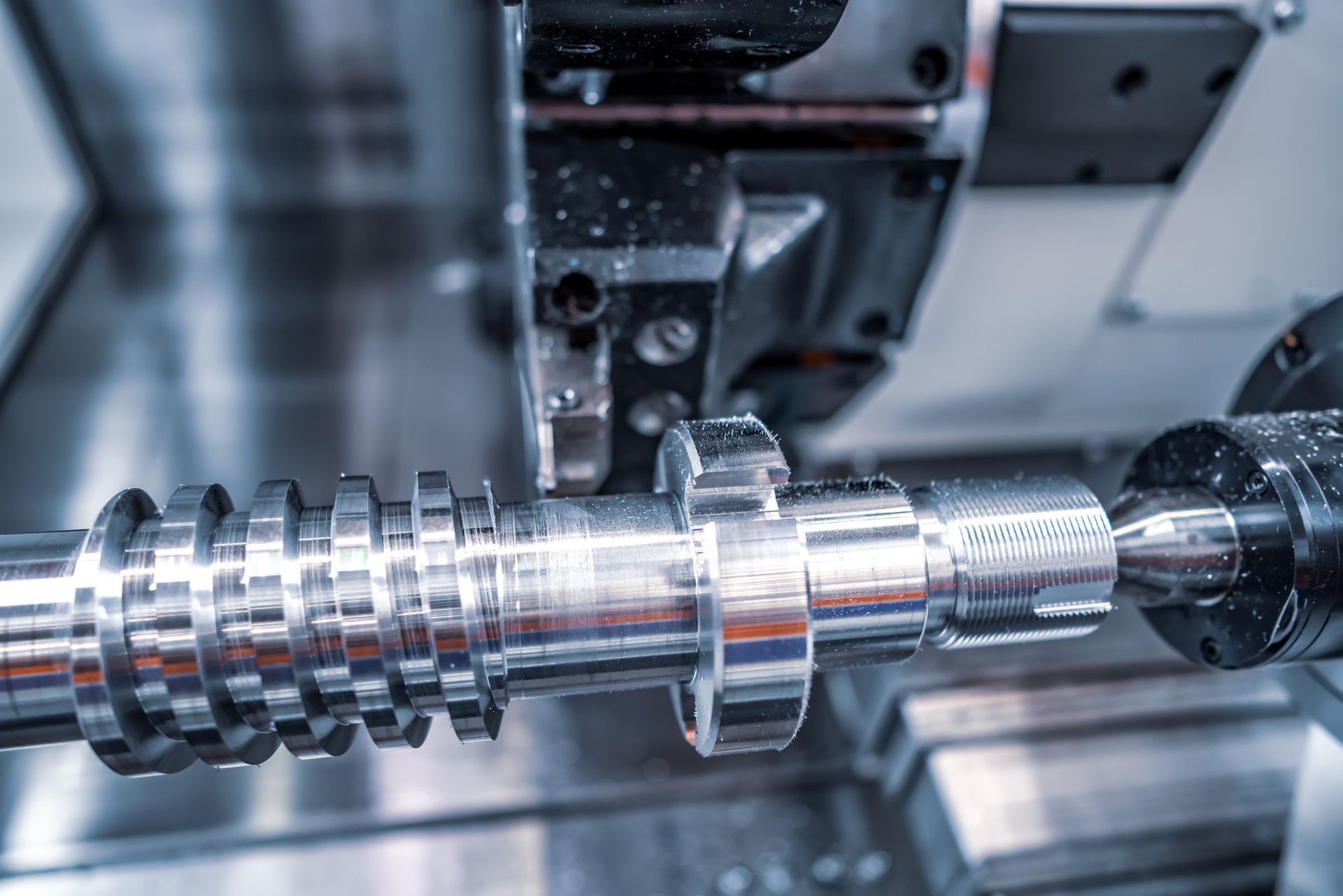

What is CNC Turning

CNC turning is a manufacturing process used to create cylindrical parts by removing material from a rotating workpiece. The process involves the use of a computer numerical control (CNC) machine equipped with cutting tools that precisely remove material to achieve the desired shape and dimensions.

Why choose us for CNC Turning

Full Capacity: by combining other technique such as wire cut , EDM etc , ,Foxstar not only machine simple parts but also machine complex part with high tolerance .

Quick turnaround : Dealing with inquiry in 8-12 hours ,to save time , any design improvement ideas will be provided with the quote . 7/24 hours sales supports could response your request .

Professional Engineering Team:Experienced engineer provide the best CNC machine solution ,material suggestion and surface finish option .

High Quality : Full inspection prior to shipping ,to guarantee you will receive qualified machined parts .

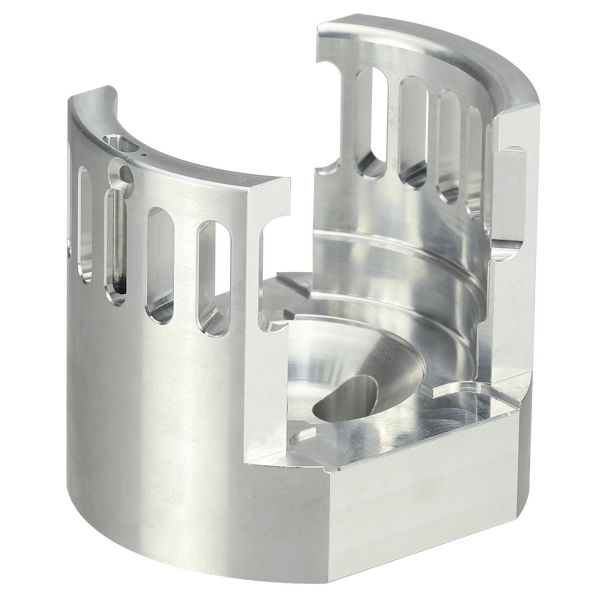

Gallery of CNC Turning Parts

CNC Turning Tolerance

Foxstar ensures precision with our CNC turning Tolerance standards. We commit to exact measurements, benefiting clients with consistent, high-quality results, Our standard tolerances for CNC turning metals are ISO 2768-m and ISO 2768-c for plastics.

| Type | Tolerance |

|

Linear dimension |

+/- 0.025 mm +/- 0.001 inch |

|

Hole diameters |

+/- 0.025 mm +/- 0.001 inch |

|

Shaft diameters |

+/- 0.025 mm +/- 0.001 inch |